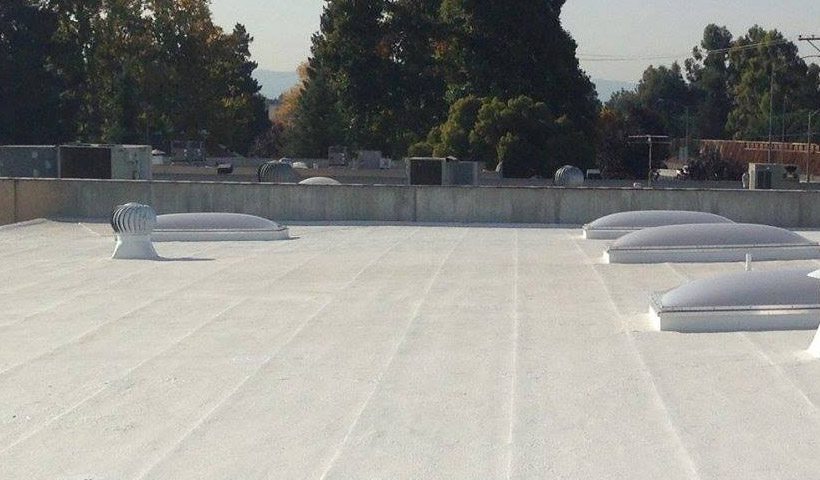

Most flat roofs look fairly similar when you’re standing on them. They’re a flat, smooth surface typically in black. However, although they look similar, there is a whole lot of difference between the various types of flat roofing in performance, longevity, ease of repair and cost. If you’re looking into flat roofing, you may want to first familiarize yourself with the four basic kinds of flat roofs and their basic advantages and disadvantages.

1. Built-Up Roofing

Built-up roofing is kind of what it sounds like, three or more built-up layers of gravel and tar. This is the oldest kind of flat roof that roofers still commonly install, and it is also typically the cheapest option upfront.

While built-up roofing is good for long-term fire prevention and can look pretty, there are reasons that newer roofing types have stolen the show. There are many disadvantages to BUR, especially during installation. It requires hot mops and kettles to install, which can be a safety risk. These roofs are also heavy, which means any building nearing its weight capacity may not be able to handle BUR.

2. Rubber and Other Membranes

As an alternative to BUR, there are several kinds of single-ply membranes. Instead of applying the roof in three or more layers, these roofs are laid down in two or fewer sheets.

One kind, rubber membrane roofs, are called EPDM for ethylene propylene diene monomer. It is a single-ply membrane material that your roofers can roll and stick right onto the roof like a highly engineered sticker. EPDM can also be treated with a reflective white coating that helps reflect heat and reduce the energy cost of the whole building.

Other single-ply membrane roofing types include TPO, thermoplastic polyolefin. This is a less expensive option than EPDM, but it is also less robust.

3. Modified Bitumen

Modified bitumen is essentially an asphalt product mixed with modifiers to make it more flexible. Modified bitumen can be turned into very large sheets like long carpets that your roofs can roll onto the roof. However, instead of having an adhesive like the other single-ply membranes we spoke about above, modified bitumen roods have to be applied with flame. This is why they are called “torch-down” roofing because roofers need to heat them up with torches as they lay them down.

Torch-down roofs have some safety concerns similar to those presented by BUR roofing as their application involves open flame. Typically, modified bitumen and BUR are not recommended as installation options for occupied buildings.

4. Metal Flat Seam Roofing

These aren’t like the metal roofs that you spot on residential buildings. Instead, they are flatter metal sheets with flattened seams that can resist water penetration. They may be steel, aluminum or copper.

No flat roof is actually entirely “flat.” In order to create positive water drainage, they all need some kind of slope. Metal flat seam roofing needs more of a slope than the other options, and it won’t be suitable for all commercial flat roof applications.